NPET (Nanoparticle Emissions Tester) 3795

The TSI Nanoparticle Emissions Tester (NPET) Model 3795 is a portable, accurate instrument capable of measuring total solid particle number emissions from a variety of diesel-powered sources, including construction machinery, buses, stationary gensets, and more. Featuring a robust, user-friendly design, the NPET can be used in the field by researchers, regulatory inspectors, and maintenance personnel alike.

List of Benefits

- Direct measurement of particle number concentration

- Sampling probe with integrated dilution

- Built in catalytic stripper

- Simple to use software

Sampling from combustion sources is often challenging due to the presence of volatile material. Volatile components are extremely sensitive to sampling conditions and can grow existing particles and form new particles through condensation.

By evaporating and oxidizing volatile particles, the NPET 3795 measures only the remaining solid particles. The NPET 3795 fully meets Swiss Regulation 941.242 for the periodic certification of diesel-powered machinery equipped with a DPF. Not only is it a rugged, mobile and a cost effective instrument, but it also comes with a software package optimized for Microsoft Windows 8 tablet allowing for ease of use in laboratory and field testing applications of on and off road equipment. A sophisticated instrument in a simple package, the NPET 3795 combines a traditionally complex system of components into a portable, robust measurement tool.

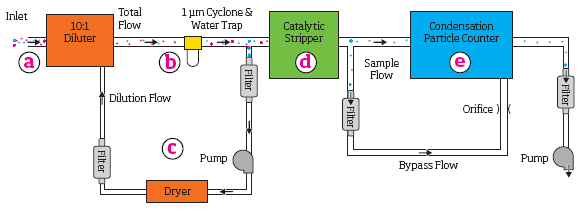

The five key design components include:

- Sampling Probe: A stainless steel sample probe with built-in diluter and removable clamp allows for easy measurement of high concentration particle number emissions directly from the tailpipe.

- Preconditioner: a 1.0μm cyclone removes large particles while a water trap removes water droplets from the exhaust gas sample.

- Recirculating dilution flow conditioner: A silica desiccant dryer and two high capacity HEPA filters efficiently dry and clean the recirculating dilution flow for continuous operation with no loss of accuracy.

- Volatile particle remover: a catalytic stripper heated to 350°C evaporates, and oxidizes volatile components to remove them from the sample stream.

- Particle counter: An isopropanol-based CPC provides accurate, direct measurement of particle number emissions at high and low concentrations over the entire range of temperature and altitude conditions.

| Specification | Detail Description |

|---|---|

| Size | 26 x 33 x 57cm / 10.2 x 13 x 22.4 inch |

| Weight | 13.1 kg / 28.9 lbs.. |

| Temperature & Pressure | -10°C to +40°C / 14°F to +104°F, 70 kPa to 106 kPa |

| Power requirement | 100 to 240 VAC, 50/60 Hz, 100 W nominal, 200 W peak |

| Ethernet | 8-wire RJ-45 jack, 10/100 BASE-T, TCP/IP |

| Software | MicrosoftWindows 7 or 8 compatible; optimized for touchscreen |

| Consumables | HEPA filters (x2), Cobalt-free silica desiccant cartridge, 99.5%+ reagent-grade isopropyl alcohol |

| Response time | T10-90% and T90-10% 40.5 seconds T0-90% 80.5 seconds |

| Sampling Interval | 10Hz (Official test mode), 1Hz (General sampling mode) |

| Particle size range Detection efficiency Max. detectable particle | 50% at 23nm 50% at 41nm Limited to 1m by inlet cyclone |

| Particle concentration range & accuracy | Single particle counting |

| Flow rates (nominal) | Instrument inlet |

| Condensing Liquid Working fluid Filling system Sample time per fill | 99.5%+ reagent-grade isopropyl alcohol, Rechargeable wick, 4 hours |

| Catalytic stripper Temperature, Volatile particle removal efficiency | 350C 99% of 30 nm, NMD polydisperse Tetracontane (C40H82) |

| Aerosol medium | Designed to sample high temperature (up to 300C), corrosive (NOx, HC, H2O, H2SO4) engine exhaust gas |

| Optional accessories | HEPA filter, Dryer cartridge, 30ml Isopropyl alcohol bottles (16), O-ring kit, Wick assembly, Hose and probe assembly, Windows8 tablet with ruggedized case and Ethernet dongle |

| Calibration | Recommended annually |

20170207-TSI-NPET3795-Brochure.pdf 564.29 KB

Manual - Current versions

20170207-TSI-NPET3795-Manual.pdf 2.87 MB

Application Notes

20170207-TSI-NPET3795-Quickstartguide.pdf 354.07 KB

Software

NanoparticleEmissionTesterSetup1.1.exe 78.11 MB